Insulation has played a pivotal role in construction for millennia. Today, it stands at the forefront of green construction, offering a path to significant energy savings and helping buildings meet Environmental, Social, and Governance (ESG) objectives. This blog delves into insulation’s evolution and its modern applications, emphasizing how it aligns with sustainability goals.

A Journey Through Time: The Evolution of Insulation

Straw being used as insulation, image from Troy Historic Village

Straw as an Early Insulator – A Glimpse from Troy Historic Village

The quest for comfortable indoor climates is as old as civilization itself. Historically, materials like straw served as primitive insulators, catering to the nomadic lifestyle with their easy availability. David Bozsaky notes the transition from these organic solutions to more durable, processed materials in the 19th century. This era introduced us to insulation panels, laying the groundwork for familiar modern materials such as rockwool and fiberglass. Fast forward to the 21st century: artificial materials dominate, with plastic foam and mineral wool leading the charge in insulation technology.

Modern Insulation: Types, Ratings, and Applications

Image from The Home Depot

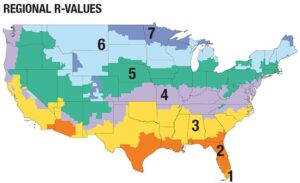

Insulation today has multiple applications, and depending on the building type and climate, the types of insulation used will vary. Different climates will require different R-values, a measurement used to indicate how well insulation can prevent heat from leaving and entering a building. Insulation is rated by its R-value, and the higher the R-value, the better the energy efficiency and climate control for the building. R-values for different climates around the United States can be seen in the graphic above. To learn more about the different types of insulation and R-values, take a look at The Home Depot’s video.

The Role of Insulation in High-Performance Buildings

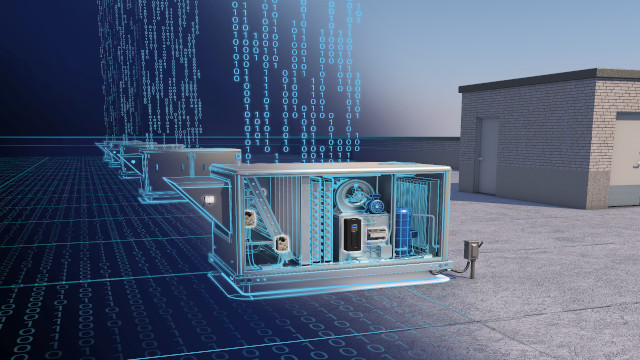

Insulation is one of the most important aspects of high-efficiency buildings and construction. It prevents the overuse of Heating, Ventilation, and Air Conditioning (HVAC), which means a reduction in energy usage for the building which directly impacts LEED and other building certification scoring.

The material provides 10-50% energy savings, depending on the building’s type and location, according to Utilities One. Reducing heat loss from the building not only reduces energy bill costs but also leads to increased tenant happiness by reducing noise carrying. High efficiency insulation can also help buildings successfully meet energy benchmarking requirements, which are in effect in over a dozen cities across the United States.

In addition, high efficiency insulation can help properties meet green building certification requirements, such as LEED. Direct benefits to building ownership from green building certifications include reducing building vacancies and increased revenue, as green certified spaces lease rates can be 20% higher compared to non-green spaces, which leads to higher rental prices. The financial benefits of high efficiency insulation are well documented in today’s case study, 435 Indio Way.

Spotlight on Sustainability: A Model of Efficiency

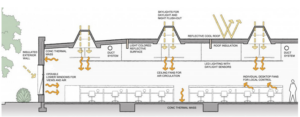

Image from RMW Architects and Interiors

435 Indio Way is an office building located in Sunnyvale, CA, in climate zone 4. The project is 31,750 sq ft, and was retrofitted to be net zero, meaning that the amount of greenhouse gases (GHGs) that the building generates is balanced with the GHGs that are removed from the atmosphere. The building was originally built in 1973. The retrofit was completed in 2013 and the building was occupied in 2014. 435 Indio Way complies with California’s Title 24 Energy Code requirements, which states that all commercial buildings must generate as much energy as they consume over 12 months by 2030.

Insulation and ventilation were important factors in the building’s net zero construction. The building has interior concrete walls and slabs, which function as a heat sink. Insulation was added to the exterior walls to promote temperature regulation. After the retrofit, the walls resulted in an R-value of R-20. Insulated foam was also added to the roof to increase insulation, which resulted in an R-value of R-40.

Image from the New Buildings Institute

Cost Savings Benefits of 435 Indigo Way

The total costs of this project at completion were $5.1 million. A code minimum building would have cost $3.5 million by comparison, meaning this building is 30% higher than a typical structure. However, the benefits of the renovation were fast and apparent. To provide a couple of examples:

- 435 Indio Way leases were filled 15 months faster than the typical market average, meaning the owners received 15 months of rent payments in this time when typically these spaces would be empty.

- Typical operating expenses, such as utilities and maintenance, were projected to cost 34% less than a minimum code building, by the design team’s own financial analyses.

Multiple areas of the building had increased financial gains, and all demonstrate this building’s financial benefits post renovation.

The evolution from straw to sophisticated insulating materials underscores humanity’s ingenuity in pursuing comfortable living environments. Today, insulation is more than just a construction material; it’s a strategic asset in the green building movement, offering both environmental and financial benefits. By embracing high-efficiency insulation, property owners can achieve ESG goals, enhance building performance, and secure a competitive edge in the real estate market.

Discover how Conservice will guide you in harnessing your portfolio’s full potential to achieve sustainability and profitability.